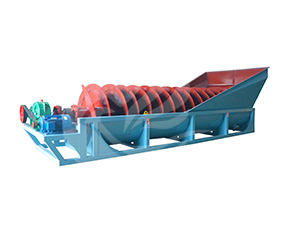

Spiral/Wheel sand washing machine is a type of equipment used for washing sand and gravel, mainly used for removing mud, impurities and dust from sand and gravel, in order to improve the quality and purity of sand and gravel.

In this series, the light-duty series are suitable for washing fine-grained materials, while the heavy-duty series are designed for washing coarse-grained materials.

01Feeding:The wheel sand washing machine pushes the sand and gravel from the feed inlet to the discharge outlet through the rotation of the impeller.

It utilizes the combined action of spiral blades and water flow, it can clean sand and gravel efficiently.

Simple structure, easy to operate and maintain.

It can effectively remove the soil, impurities and dust in the sand and gravel.

Equipped with advanced control system to realize automatic operation.

Suitable for cleaning various sand and gravel.

1. Construction industry:used for washing construction sand, concrete aggregate etc., removing impurities and soil, improving the purity of sand and gravel materials.

2. Mining industry:used to wash sand and gravel materials, remove impurities and improve the grade and quality of ores.

3. Water conservancy and hydroelectric engineering:used to wash sand and gravel aggregate.

4. Highway and railwayconstruction:used to wash roadbed and pavement materials, providing high hardness and wear-resistant sand and gravel materials.

5. Glass Industry:used to wash quartz sand and produce high purity sand and gravel for glass manufacturing.

6. Metallurgical industry:used to wash metallurgical slag to produce recycled sand and gravel for metallurgical furnace materials or building materials.

| Model | Type | Spiral Diameter(mm) | Feed Particle Size (mm) |

Water Consumption(mm) | Production Capacity (t/h) |

Power (kw) |

Overall Dimension (L*W*H) (mm) |

Weight (T) |

| Light-duty Single Spiral | XL-750 | Ø750 | <10 | 6-60 | 10-30 | 7.5 | 8000*2343*1530 | 2.7 |

| XL-1000 | Ø1000 | <10 | 6-63 | 30-40 | 7.5 | 8000*2490*1530 | 3.5 | |

| XL-1200 | Ø1200 | <10 | 9-63 | 50-70 | 11-15 | 9070*2650*1530 | 5.3 | |

| XL-1500 | Ø1500 | <10 | 10-80 | 80-120 | 11-15 | 9070*2650*1638 | 6.4 | |

| XL-1800 | Ø1800 | <10 | 13-168 | 120-180 | 22 | 9070*2830*1900 | 12.7 | |

| Light-duty Double Spiral | 2XL-762 | Ø762 | <10 | 20-150 | 140 | 2×11 | 11580*3965*2370 | 7.4 |

| 2XL-914 | Ø914 | <10 | 60-300 | 200 | 2×15 | 9310*3940*3870 | 11.3 | |

| 2XL-1118 | Ø1118 | <10 | 60-600 | 350 | 2×22 | 9070*3890*1900 | 16.7 | |

| Heavy-duty Single Spiral | XLZ-1200 | Ø1200 | <60 | 160-220 | 80-125 | 22 | 11580*5226*2370 | 8.8 |

| XLZ-1500 | Ø1500 | <60 | 200-300 | 125-175 | 30 | 6980*1200*1340 | 9.8 | |

| XLZ-1800 | Ø1800 | <75 | 250-350 | 180-250 | 37 | 7400*1380*1950 | 12.2 | |

| Heavy-duty Double Spiral | 2XLZ-762 | Ø762 | <60 | 300-400 | 100-150 | 2×22 | 6980*2091*1340 | 16.8 |

| 2XLZ-914 | Ø914 | <60 | 350-450 | 150-200 | 2×30 | 7120*2146*1590 | 18.9 | |

| 2XLZ-1118 | Ø1118 | <75 | 450-550 | 200-300 | 2×37 | 8500*2861*2150 | 22.2 |

| Model | Impeller Diameter (mm) |

Feed Particle Size (mm) |

Production Capacity (t/h) |

Motor Type | Motor Power (kw) |

Weight (T) |

Overall Dimension (L*W*H)(mm) |

| XSD2610 | Ø2600 | ≤10 | 20-50 | Y160L-8 | 7.5 | 2.68 | 3321*2312*2683 |

| XSD2816 | Ø2800 | ≤10 | 30-70 | Y180L-8 | 15 | 5.3 | 3810*2820*2883 |

| XSD3016 | Ø3000 | ≤10 | 50-100 | Y200L-8 | 15 | 6.5 | 3830*2972*3200 |

| XSD3620 | Ø3600 | ≤10 | 80-150 | Y255S-8 | 18.5 | 9.8 | 4456*3479*3688 |

| XSD3624 | Ø3600 | ≤10 | 150-200 | Y225M-8 | 22 | 10.5 | 4300*3700*3700 |

| XSD4030 | Ø4000 | ≤10 | 200-280 | Y250M-8 | 30 | 14 | 5300*4080*4100 |

Copyright © 2020 Henan Mingheng Heavy Industry Machinery Co., Ltd. Power by yisainuo