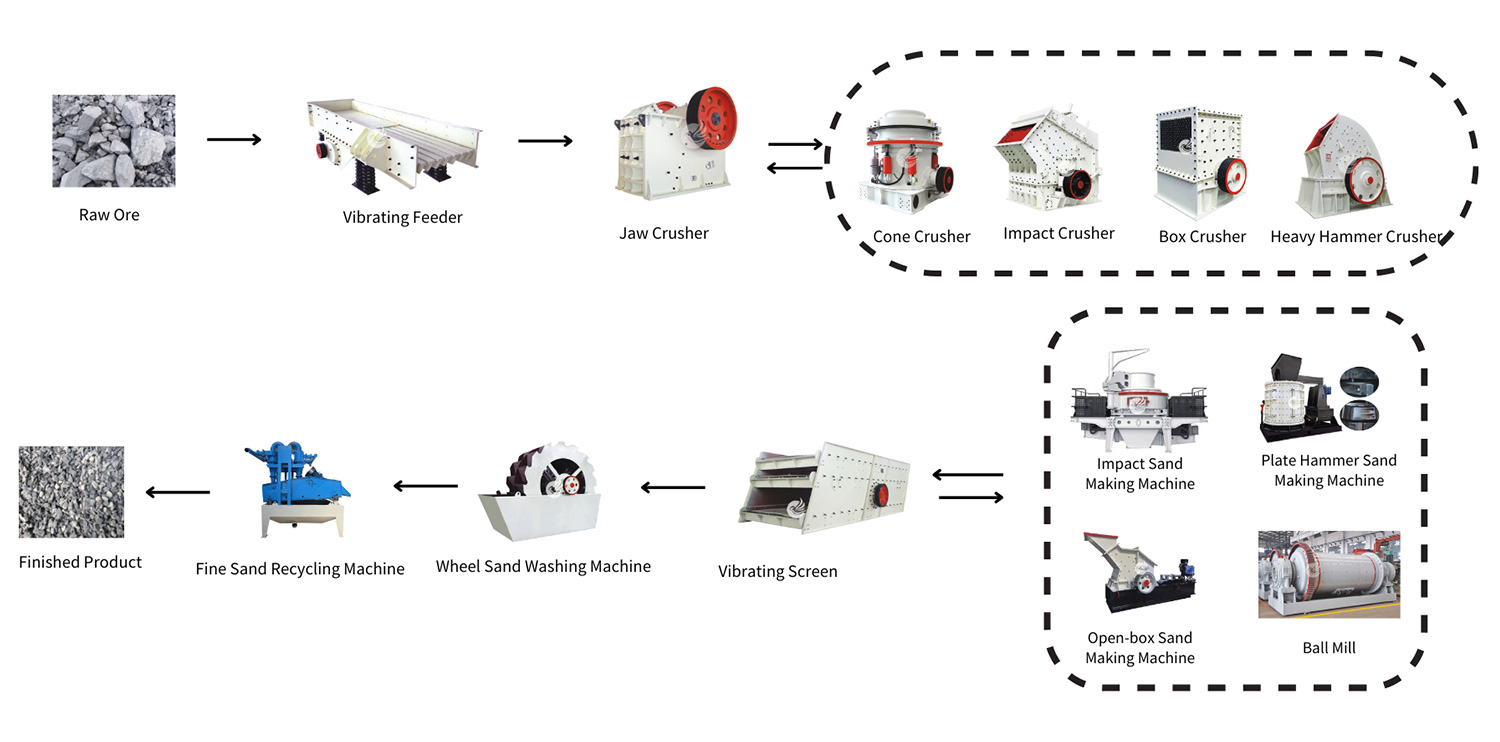

Adopting advanced crushing and sand making equipment, the production efficiency is high, which can meet the demand of large-scale artificial sand.

Through multi-stage screening equipment, various specifications of artificial sand (such as 0-5mm, 0-3mm etc.) can be produced.

Adopt impact sand making machine or shaping equipment to ensure that the psrticle shape of artificial sand meets the construction standards.

Equipped with dust removal and sewage treatment equipment to reduce dust and sewage pollution, in line with environmental requirements.

It can deal with a variety of hardness of ores and rocks, such as limestone, granite, basalt, river pebbles etc..

Copyright © 2020 Henan Mingheng Heavy Industry Machinery Co., Ltd. Power by yisainuo