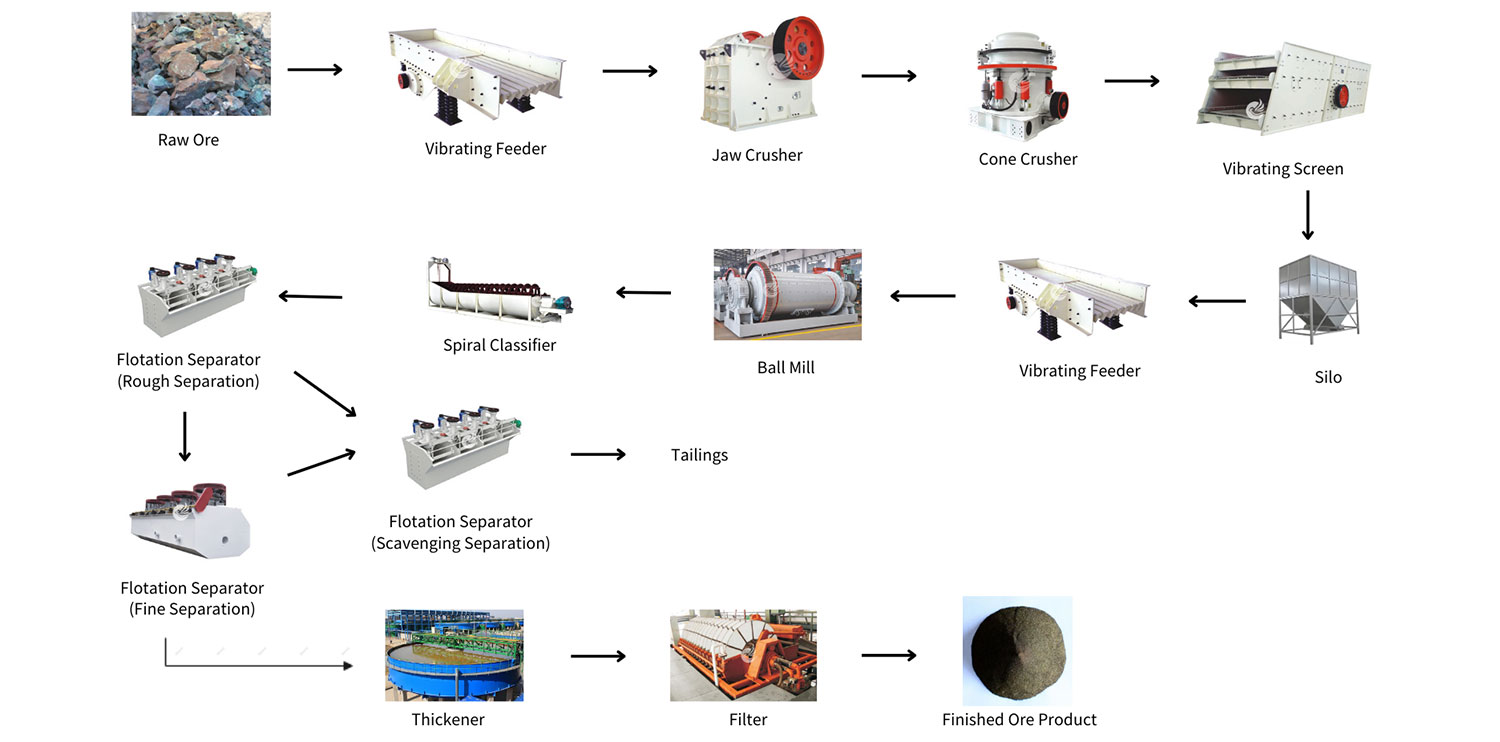

The flotation process has a high recovery rate for copper sulfide/nickel sulfide/lithium pyroxene and lithium mica ores.

The process can be adjusted according to the type of ore (e.G. Oxidized copper ore needs to be combined with leaching process, oxidized nickel ore needs to be combined with pyrometallurgy or hydrometallurgy, lithium mica needs to be combined with chemical beneficiation process).

The flotation process needs to control the use of chemicals and wastewater treatment.

Copyright © 2020 Henan Mingheng Heavy Industry Machinery Co., Ltd. Power by yisainuo