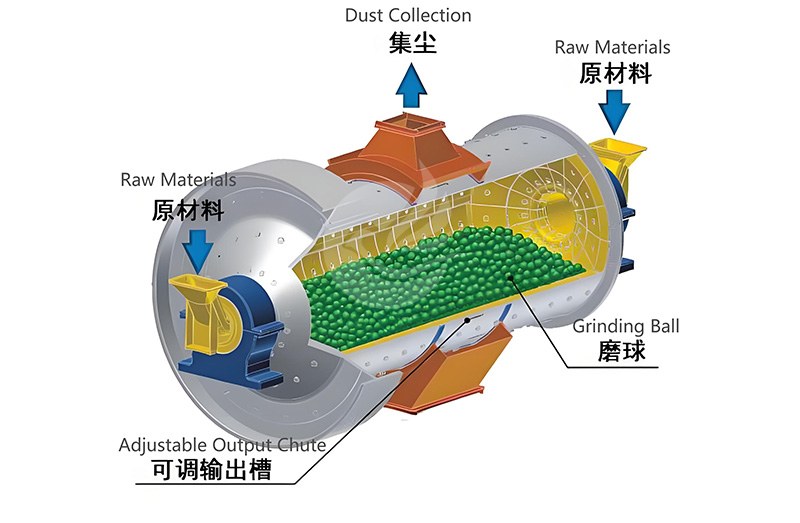

Ceramic ball mill is mainly used for material mixing and grinding, both dry and wet grinding,which can adopt different liners according to the production capacity, material density and hardness to meet various requirements.

It features a motor with an auto-transformer reduced voltage start to lower the starting current.

Suitable for small batch and multi-variety production.

It can realize ultra-fine grinding of materials.

The liner can be made of ceramic, silica, rubber and metal, which can be adapted to different materials.

Simple structure, easy to operate and maintain, safe to use, stable and reliable performance.

1.Ceramic industry: used for fine grinding of ceramic glaze and ceramic raw material.

2.Chemical industry: used for the grinding of pigments and dyes.

3.Building materials industry: used for the grinding of cement and slag.

4.Electronic industry:used for the fine grinding of electronic materials.

|

Model |

Production Capacity (t/h) |

Cylinder Speed (r/min.) |

Motor Power (kw) |

Weight (T) |

|

TCQ910×1120 |

0.2 |

36 |

5.5-11 |

2.6 |

|

TCQ1200×1400 |

0.5 |

32 |

11-18.5 |

4.3 |

|

TCQ1500×1800 |

1 |

28 |

15-22 |

7.5 |

|

TCQ1800×2100 |

1.5 |

26 |

18.5-30 |

10.5 |

|

TCQ2100×2100 |

2.5 |

22 |

22-37 |

14 |

|

TCQ2200×2400 |

3 |

20 |

28-45 |

18 |

|

TCQ2500×2900 |

5 |

16 |

37-55 |

26 |

|

TCQ2800×3700 |

8 |

14.5 |

55-75 |

35 |

|

TCQ3000×3700 |

10 |

14 |

75-90 |

46 |

|

TCQ3200×4600 |

15 |

13.5 |

90-110 |

63 |

Copyright © 2020 Henan Mingheng Heavy Industry Machinery Co., Ltd. Power by yisainuo